MANUFACTURING

MANUFACTURING

MyLogic is the most comprehensive Manufacturing software and the one that best adapts to every type of industry and production structure.

Manufacturing 4.0 | Online Management of Multiple Companies and Plants

MyLogic Manufacturing 4.0 manages production processes in real time across multiple companies and plants.

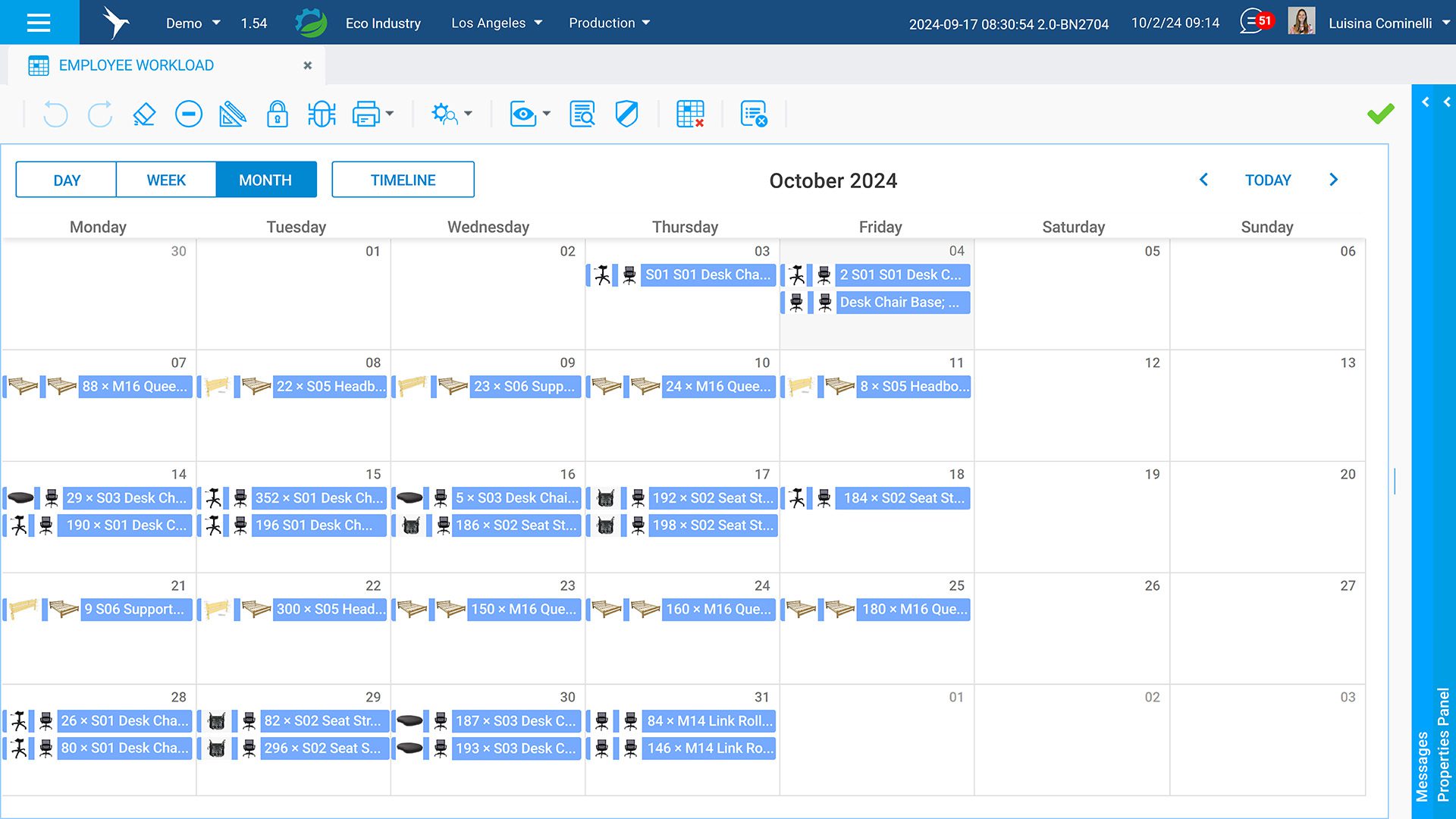

With MyLogic’s mobile interface, paperwork on the shop floor is eliminated, allowing operators to view their assignments and report completed tasks from any device.

MRP | Production Planning | Cross-Area Integration

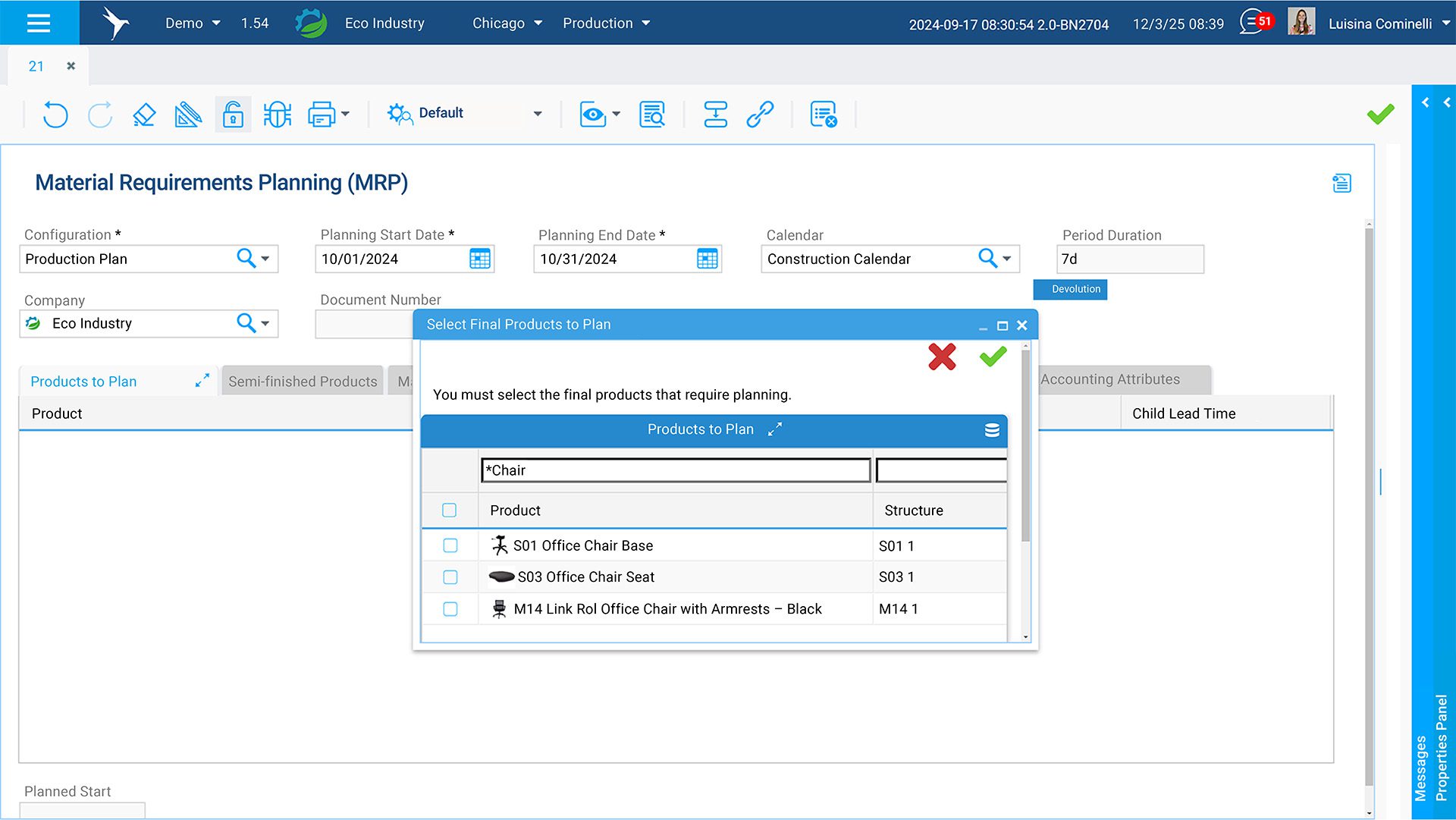

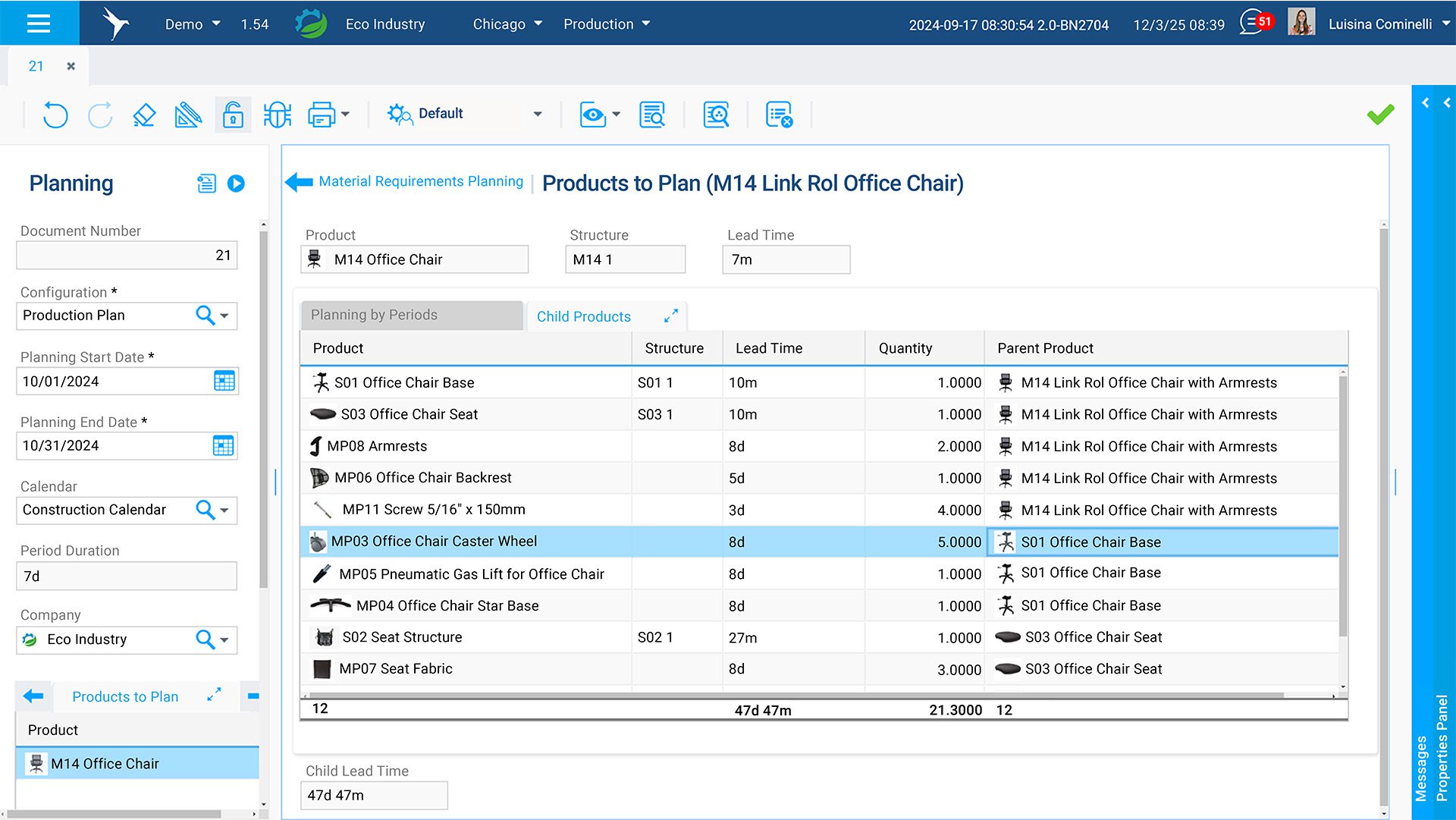

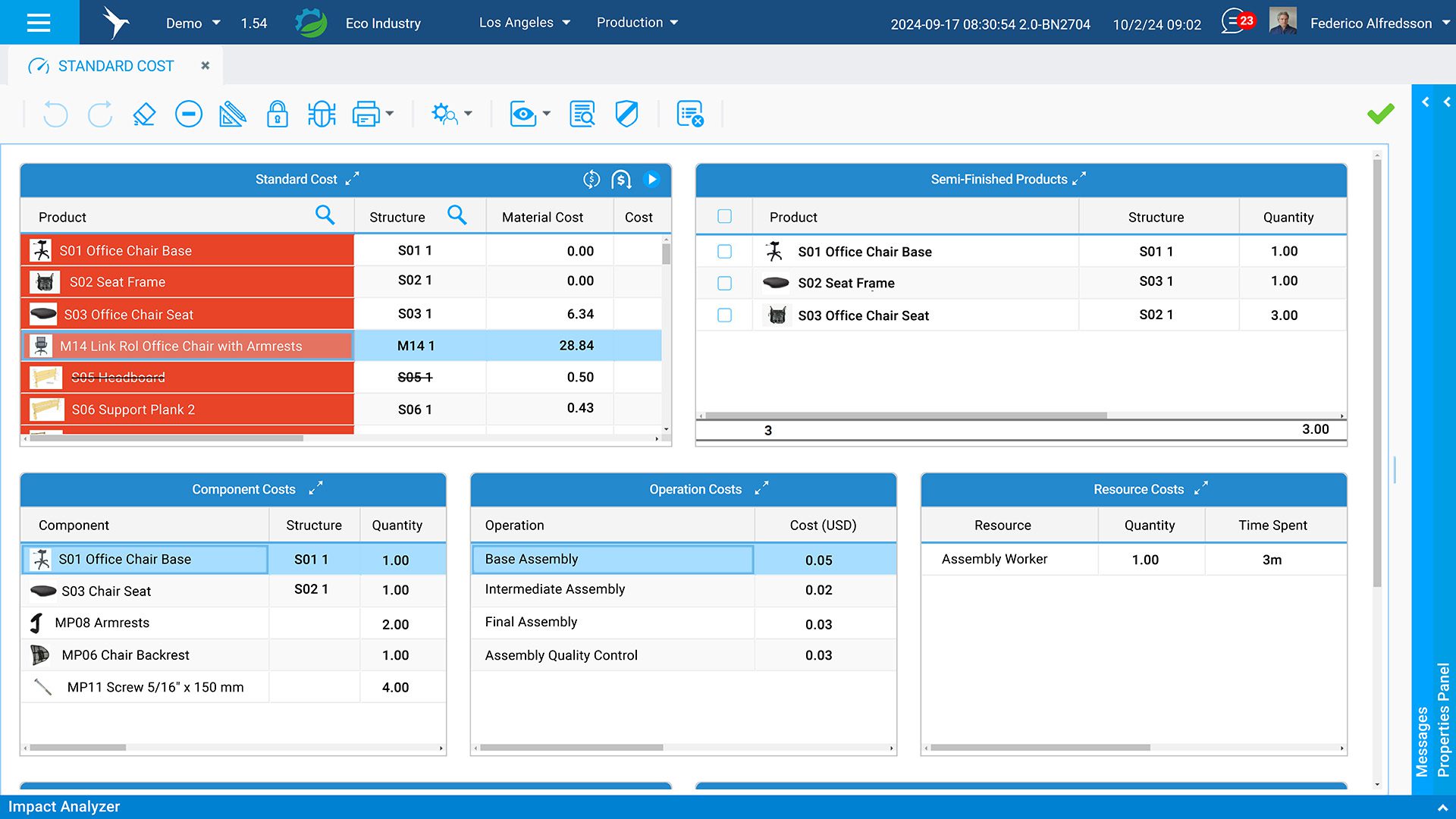

Material Requirements Planning (MRP) optimizes production and the supply chain by forecasting resource and input needs, then comparing them against installed capacity and available stocks of raw or semi-finished materials. This minimizes idle capacity and proactively triggers the creation of production orders and supply purchase requests.

In MyLogic, all areas of the company are seamlessly integrated with manufacturing, drawing on information such as projected sales, inventory levels, pending purchases, replenishment costs, employee leave licenses, equipment maintenance, and more.

In MyLogic, all areas of the company are seamlessly integrated with manufacturing, drawing on information such as projected sales, inventory levels, pending purchases, replenishment costs, employee leave licenses, equipment maintenance, and more.

Outsourced Manufacturing | Contract Manufacturing

MyLogic manages the outsourcing of production processes, covering everything from planning based on each supplier’s available capacity to the generation of work and purchase orders, the shipment and receipt of materials, quality control, traceability, invoicing, and payment.

Other functionalities

Procurement

- Integrated and Adaptable Procurement Workflows

- Supplier Self-Management | Bidding | Supplier-Specific Price Lists

- Replenishment Strategies with Automatic Purchase Order Generation

- Alerts for Discrepancies Between Invoice and Purchase Order

- Quality Control

- Open Purchase Orders and Contracts

sales

- Integrated and Adaptable Sales Workflows

- Contract Billing

- Cross-Selling and Up-Selling Intelligence

- Customer-Specific Price Lists

- Global and Item-Level Charges/Discounts

- Automatic Generation of Product Variants

- Sales Pricing Based on Purchase Costs or Manufacturing Costs

Shipments

- Comprehensive Import Management

- Projected and Actual Expenses per Shipment

- Financial Planning for Imports

- Shipment Cost Allocation for Sales Price Calculation

- Tools for Evaluating the Import Process

E-COMMERCE

- B2C and B2B E-Commerce

- Integration with E-Commerce Platforms

- Centralized Management of Listings

- Inventory Management

- Product Variants

- Sales Invoicing

Point of Sale

- POS Integrated with Back Office in Real Time

- Multi-Device Mobile Access

- Sales Strategies | Bank-Partnered Discounts and Promotions

- Integration with Card Payment Validation Systems

- Gift Cards | Exchange Receipts | Vouchers | Deposits | Deferred Delivery

- Cash Drawer Opening, Cash Drop, and Closing

- Industry-Specific Functionalities

Fixed Assets

- Fixed Asset and Equipment Allocation

- Maintenance Plans and Tasks

- Maintenance Requests and Work Orders

- Preventive and Corrective Maintenance

- Depreciation Based on Usage and/or Time

- Certificate and Insurance Expiration Control

Costs

- Multi-company and Multi-currency Cost Management

- Last Cost | Weighted Average Cost | Replenishment Cost

- Optimal Purchase and Production Batches

- Automatic Sales Price Calculation based on Costs

WMS and Inventory

- Available and Projected Stock

- Multi-Warehouse Management for Companies and Branches

- Real-Time Location-Based Stock

- Dispatch Optimization and Route Sheets

- Warehouse Tasks

- Inventory Control

Accounting

- Real-Time Multi-Company Balance Sheets

- Automated Multi-Currency Posting

- Consolidated Global Information

- Detailed allocation by Multiple Cost Centers and Accounting Attributes

- Budgetary Accounting

- Inflation Adjustments and Revaluations

- Tax Compliance

Finance

- Consolidated Financial Position Across Companies and Countries

- Cash Flow | Projections | Scenario Simulation

- Expense Planning

- Multiple Cash Flow Management

- Manual and Automated Account Reconciliation

- Automatic Quotation Updates

Pre-Sales CRM

- 360° View and Sales Cycle Traceability

- Integration with Lead or Contact Generation Platforms

- Negotiations, Progress Level, and Closing Probability

- Transformation of Opportunity into Sales Order

- Monitoring of Distributor and Channel Activity

- Sales Projections and Statistics Charts

After-Sales CRM

- Case or Ticket Management

- Workflow Configuration

- Centralized Task Tracking

- Self-Service Portal for Clients

Projects

- Planning and Tracking by Milestones, Tasks, and Goals

- Quoting Based on Material, Resources, Costs, and Profit Calculations

- Integration with Manufacturing | MRP

- Progress Billing with Deviation Alerts

- Project Version Control

- Progress Monitoring, Deviation Detection and Management

- Templates by Project Type